Application:

. High power and capacity in crushing stones

. Manufacturing wear parts from manganese steel

. Homogeneity of external load

. Quick and easy replacement of spare parts

. Beautiful design and reliable performance

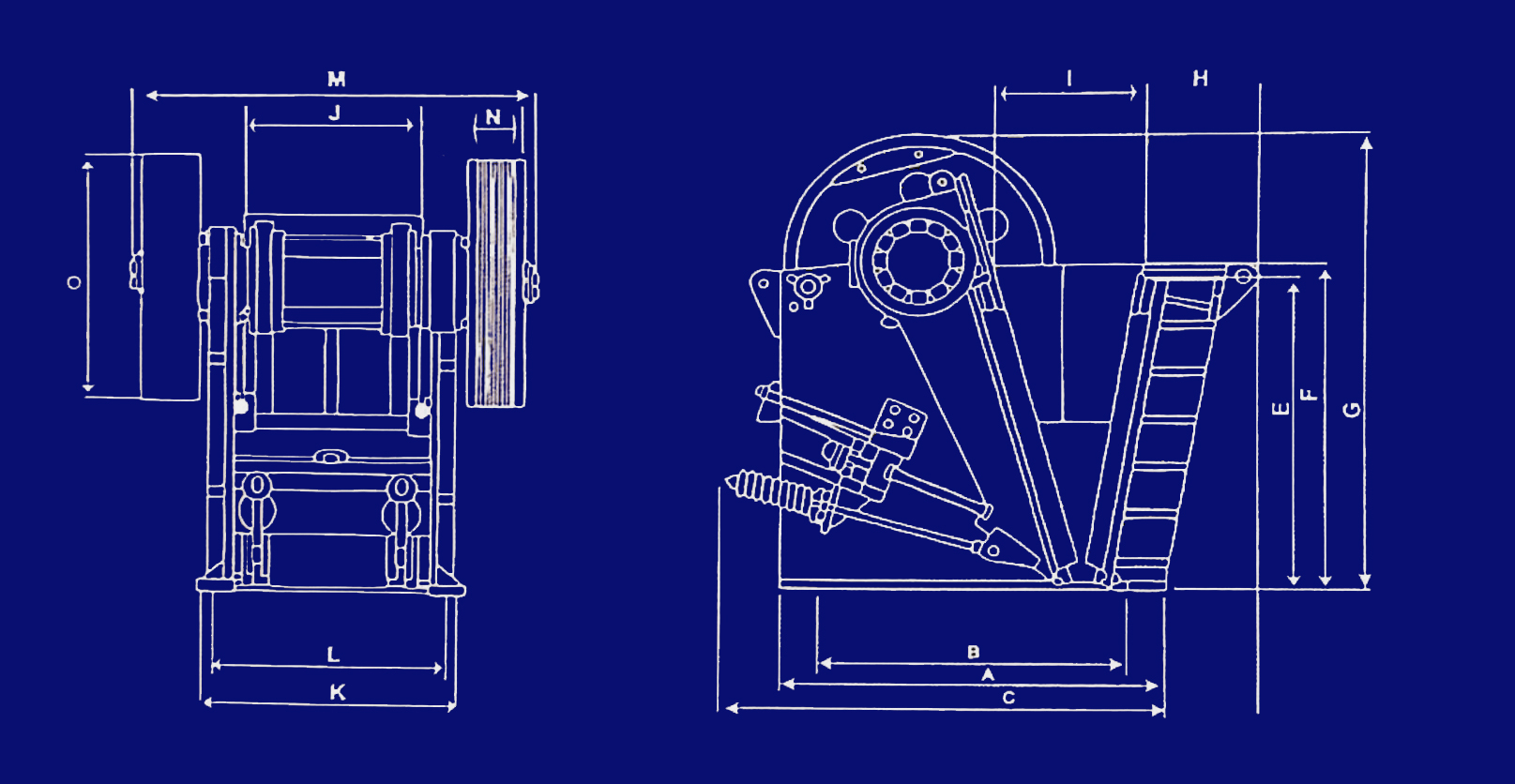

Jaw crusher

Jaw crushers with different inlets are used to crush rocks at the beginning of the processing process. All parts that come into contact with the rock are made of replaceable wear-resistant sheet metal. The shoulders are made of wear-resistant manganese steel with molybdenum, which are easily replaceable and can be used in both directions. All shafts are made of Mo40 steel. The type of welding used in the machine is Co2, which is considered the most resistant welding. The design of the bearings is such that it can withstand up to six times the pressure of the rocks.

Jaw crushers are used in the most basic processing process, and two fixed and movable jaws are used in this crusher. Coarse rocks are placed between these two jaws and crushed under high pressure and impact. The movement of the movable jaw is carried out in different ways to produce the most force to crush the rocks.

All rights of this website belong to Mohammadi Machine Industries. Designed and developed by Laraman Smart Solutions